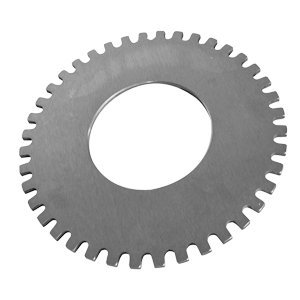

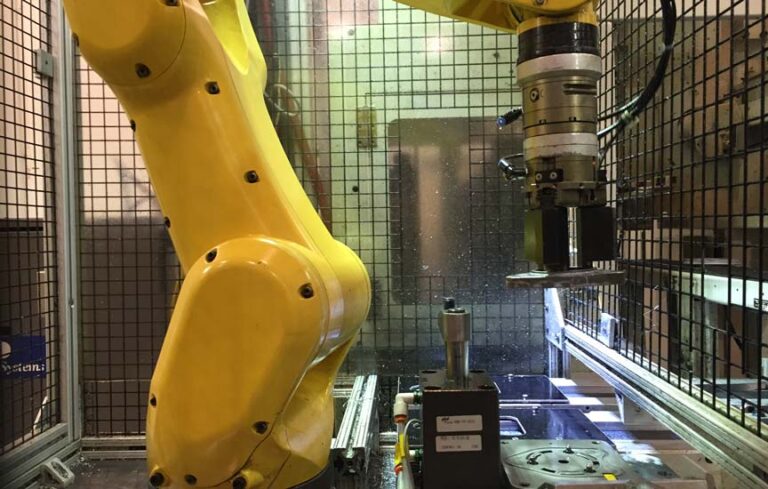

Many of the components we manufacture require post-processing heat treatment to enhance strength, hardness, and wear resistance. Precision Resource ensures precise heat treatment through a combination of internal capabilities and partnerships with approved suppliers, carefully managing the process to maintain dimensional integrity and mechanical performance.

Our deep expertise allows us to develop optimized processing techniques that achieve the necessary material properties while minimizing distortion. We apply this knowledge to both in-house and outsourced operations, ensuring defect-free, high-quality components.

Our Mexico division features in-house hardening, carburizing, and nitro-carburizing capabilities, utilizing two UBC batch furnaces and a continuous belt furnace for efficient high-volume production. Additionally, we offer induction hardening across multiple locations.