Precision Resource’s Kentucky Division (PR-KY) has received a prestigious honor from ZF, a global leader in driveline and chassis technology as well as active and passive safety technology. PR-KY was awarded the ZF Supplier Performance Award for Excellence in Collaboration and Quality Performance during 2024 and 2025. This distinction places PR-KY among the top three […]

Read More

Precision Resource is pleased to announce that we will be exhibiting at Blechexpo 2025, taking place October 21–24 at the Messe Stuttgart in Stuttgart, Germany. Join us at Hall 4, Booth #4110 to discover how our expertise in precision machining, fineblanking, and additive manufacturing delivers smarter, faster, and better solutions for sheet metal processing and […]

Read More

Precision Resource is excited to announce that we will be attending SEMICON West 2025, taking place October 7–9 at the Phoenix Convention Center in Phoenix, Arizona. Visit us at Booth #792 to learn more about our advanced manufacturing capabilities, including precision machining, fineblanking, and additive manufacturing. Our team will be on hand to discuss how […]

Read More

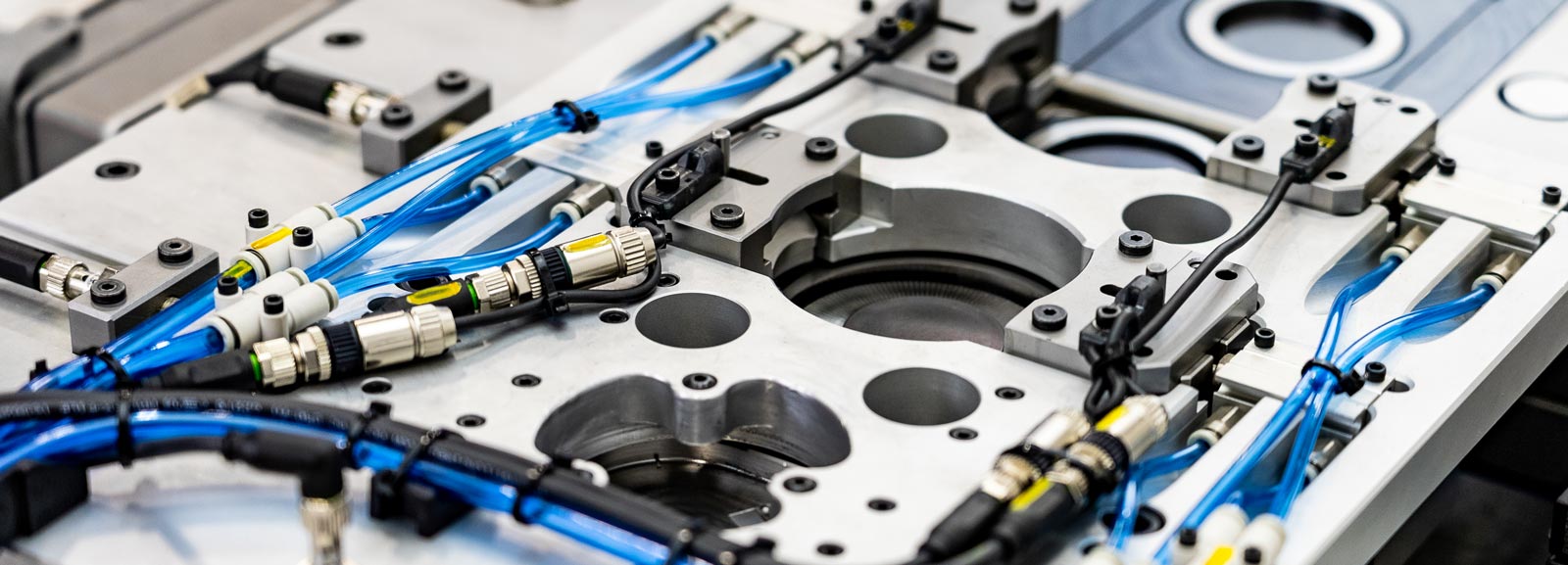

Join Precision Resource at The Battery Show North America 2025, where industry leaders gather to explore the latest advancements in automotive and battery technology. We’ll be at Booth #5825, showcasing how our vertically integrated capabilities—precision machining, fineblanking, and advanced assembly—deliver the critical metal components today’s vehicles demand. From high-volume production to complex part geometries, we […]

Read More

A modernized platform that reflects our growth beyond fineblanking and our commitment to delivering end-to-end solutions Shelton, Connecticut, July 1, 2025 — Precision Resource, a global leader in precision metal component manufacturing, is proud to announce the launch of its newly redesigned website, now live at www.precisionresource.com. The launch marks a major step in showcasing the […]

Read More

We’re excited to attend this year’s event in Norfolk, VA on July 29–30 to showcase how our vertically integrated solutions meet the evolving needs of the U.S. Navy and Marine Corps. From fineblanking to complex machining and precision assemblies, our components are built for mission-critical performance. 📍 Come meet us in Norfolk. Let’s talk defense […]

Read More

GM Honors Precision Resource Connecticut with 2024 Supplier Quality Excellence Award Shelton, Connecticut, June 12, 2025 — Precision Resource’s Connecticut division proudly earned the 2024 Supplier Quality Excellence Award (SQEA) from General Motors, a recognition reserved for GM’s top-performing global suppliers. The award celebrates the Shelton team’s unwavering commitment to delivering consistent quality, reliability, and […]

Read More

Fineblanking now can produce not only flat parts, but also those with 3-D features, often to size and position tolerances of less than ±0.025 mm. It also offers extremely high part-to-part repeatability; the first part and the millionth part are identical. A confluence of technologies has made such parts a reality (see Figures 1 and 2). […]

Read More

If you work in precision manufacturing, you’ve likely come across the terms ‘fineblanking’ and ‘fine blanking.’ While they look similar, one is the industry-standard term—and understanding the distinction can make a difference in how you communicate within the field. Fineblanking or Fine Blanking – Which is Correct? In essence, fineblanking and fine blanking refer to […]

Read More

When it comes to precision manufacturing, choosing the right process can make all the difference. Let’s compare fineblanking with conventional stamping to see why fineblanking stands out in key areas. 1. Edge Quality: In conventional stamping, rough edges are often left behind, necessitating additional finishing steps to achieve the desired quality. Fineblanking, on the other […]

Read More