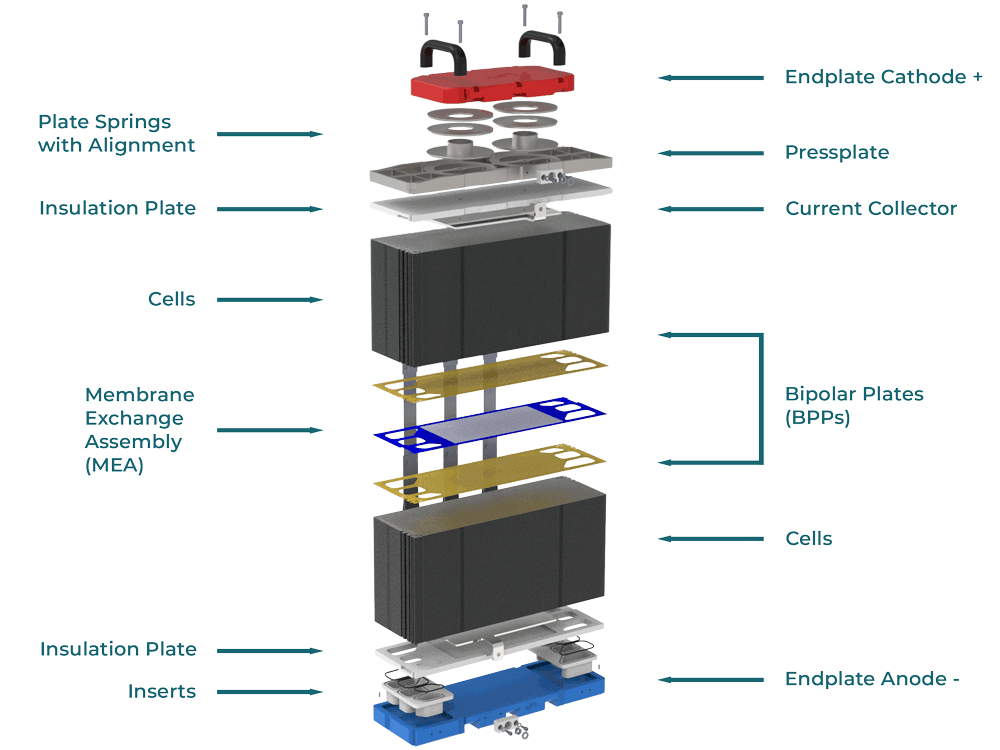

Metallic Bipolar Plate (MBPP) Expertise

PRECISION RESOURCE IS YOUR TRUSTED PARTNER FOR INNOVATIVE METAL BIPOLAR PLATE DEVELOPMENT AND MANUFACTURING SOLUTIONS.

Our advanced manufacturing processes, including multi-stage forming technology, offer a new era of design and production, enabling the manufacturing of complex, ultra-precise flow-field geometries and functional integrations that enhance both cell performance and durability.

With the ability to work with materials like stainless steel and titanium, we provide robust, high-tensile substrates capable of withstanding demanding applications. Partnering with industry leaders to accelerate development and drive innovation in hydrogen technologies, we are a trusted partner from sub-scale and full-scale prototyping for bench testing through to series production.