Precision Manufacturing Solutions for the Medical Industry

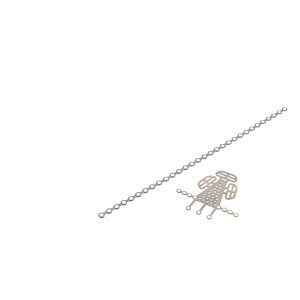

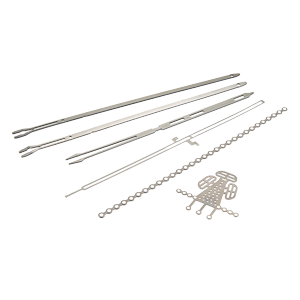

Precision Resource supports leading medical device manufacturers by producing critical components through fineblanking, metal additive manufacturing, precision machining, and assembly. With more than 75 years of experience, we provide cost-effective, high-volume solutions for essential parts used in diagnostic equipment, surgical instruments, orthopedic tools, and other life-saving technologies. Our advanced capabilities and ongoing investment in manufacturing innovation allow us to meet the strict quality and performance standards of the medical industry—delivering precision-engineered components that support better patient outcomes and more efficient care.