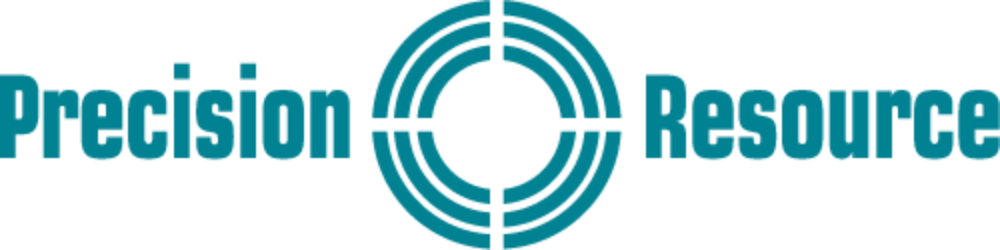

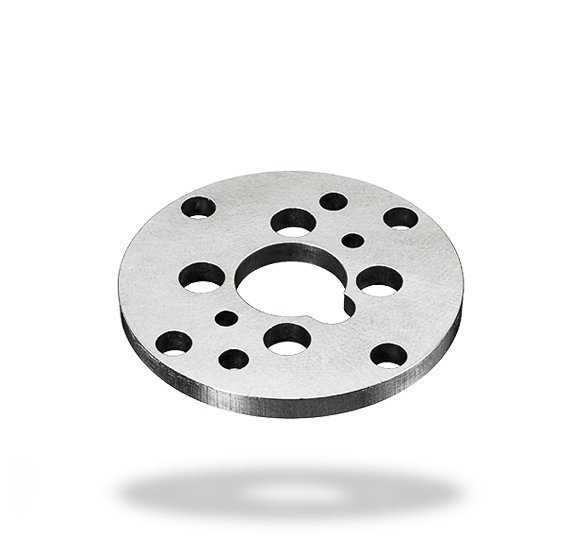

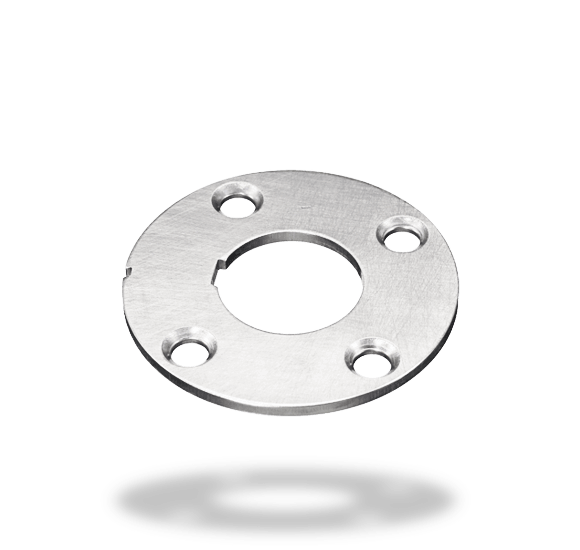

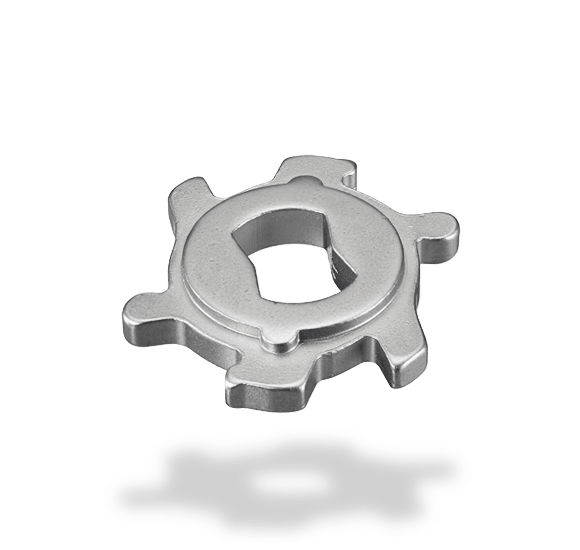

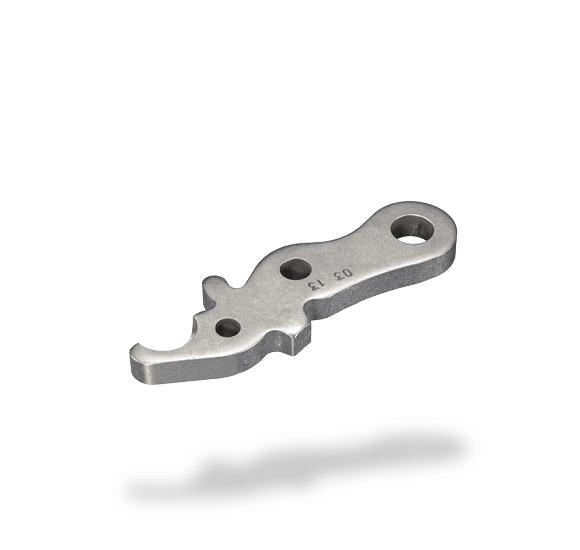

FineBlanking is a hybrid metal forming process combining the technologies of stamping and cold extrusion.

Triple-action presses, combined with specially designed tooling, produce parts impossible to make with any other stamping process, allowing for complex geometries, intricate shapes, and features that would be unattainable with conventional stamping methods.

A recognized leader in the development of fineblanking technology, Precision Resource operates more than 100 fineblanking presses, more than any other company in the world. With press sizes ranging from 40 to 1600 tons, Precision Resource has the widest range in the industry, ensuring we can accommodate a wide variety of projects, from small, intricate components to large, complex parts. This flexibility allows us to meet the unique production needs of our customers, regardless of the size or complexity of their requirements.