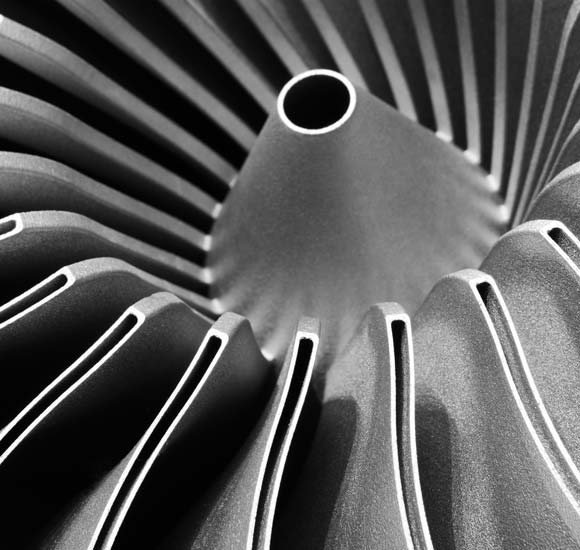

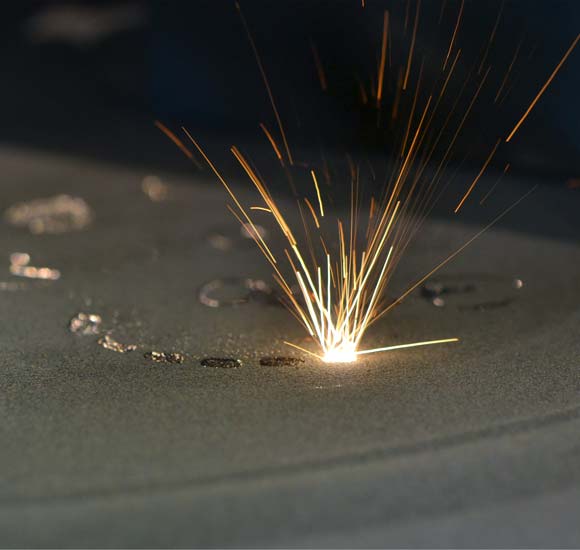

Metal additive manufacturing, or 3D printing with metals, is transforming the way we build, design, and produce precision components.

By layering metal powder to create complex shapes, we achieve what traditional methods cannot. Leverage our expertise to help overcome design and production limitations with our advanced additive manufacturing solutions.

Precision Resource is uniquely positioned to deliver fully finished metal 3D printed parts by combining our deep additive expertise with extensive subtractive machining capabilities and robust, integrated quality management systems. This end-to-end approach means that every part meets exact specifications and is ready for performance-critical applications.