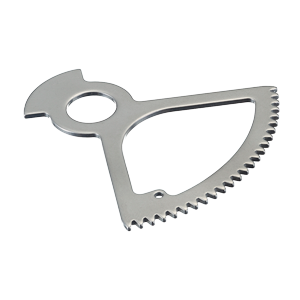

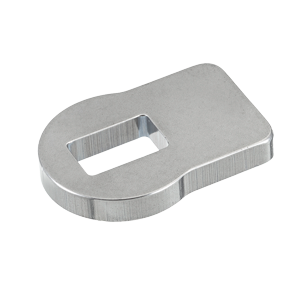

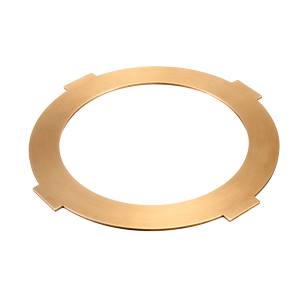

Advanced Manufacturing for Critical Aerospace Components

As a leading provider of aerospace machining and metal additive manufacturing, we manufacture high-precision components that meet the rigorous demands of the aviation and space industries. Our advanced manufacturing capabilities, backed by AS9100D certification and ITAR registration, reflect out unwavering commitment to accuracy, quality, and compliance with stringent industry requirements.